Introduction

Unveiling the Innovation of Bird Fleshing Machines

In the intricate world of poultry processing, technological advancements play a pivotal role in optimizing efficiency, ensuring hygiene, and meeting the demands of a rapidly evolving industry. One such innovation that has revolutionized the poultry processing landscape is the bird fleshng machine. This introduction sets the stage for a deep dive into the functionality, applications, and impact of these machines, shedding light on their significance in streamlining processes, enhancing quality, and contributing to the sustainable evolution of the poultry processing sector. Join us as we explore the intricacies of bird fleshing machine, unraveling the feathers of innovation that define their role in modern poultry processing.

Table of Contents

Unveiling the Innovation of Bird Fleshing Machines: A Comprehensive Exploration

In the dynamic realm of poultry processing, the integration of cutting-edge technologies has become paramount to meet the escalating demands of the industry. Among these innovations, bird fleshing machines stand out as a transformative force, reshaping the landscape of poultry processing with their efficiency, precision, and impact on product quality. This comprehensive article navigates through the intricacies of bird fleshing machines, providing an in-depth analysis of their functionality, applications, and the far-reaching implications for the poultry industry.

1. Introduction to Bird Fleshing Machines

Defining the Technology:

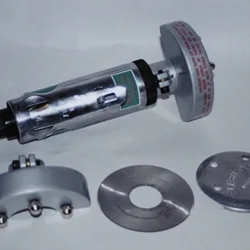

Bird fleshing machine represent a technological breakthrough designed to streamline the feather removal process in poultry processing. Unlike traditional manual methods, these machines leverage automation to enhance efficiency and accuracy.

Purpose and Significance:

Explore the primary purpose of bird fleshing machines, emphasizing their role in expediting the processing of poultry carcasses. Understand the significance of this technology in meeting the growing demands of the modern poultry industry.

2. How Bird Fleshing Machines Work

Mechanical Processes:

Delve into the mechanical intricacies of bird fleshing machines. Uncover the step-by-step processes involved in feather removal, from the initial positioning of the carcass to the precise mechanisms responsible for efficient plucking.

Automation and Precision:

Highlight how automation contributes to the precision of feather removal. Discuss the technological features that enable these machines to adapt to different bird sizes and species, ensuring uniformity in processing.

3. Applications in Poultry Industry

Streamlining Poultry Processing:

Examine how bird fleshing machines streamline poultry processing operations. Discuss their role in reducing processing time, labor requirements, and the overall operational costs for poultry plants.

Scale and Efficiency:

Explore the scalability of these machines, considering their efficiency in handling large volumes of poultry carcasses. Analyze how their implementation aligns with the scale of operations in various poultry processing facilities.

4. Enhancing Processing Efficiency

Reduction in Manual Labor:

Discuss how bird fleshing machines contribute to a significant reduction in manual labor. Explore the implications of this shift on overall efficiency, cost-effectiveness, and the well-being of workers in poultry processing plants.

Impact on Production Rates:

Examine the correlation between the use of bird fleshing machine and increased production rates. Illustrate how these machines contribute to meeting market demands by accelerating processing timelines.

5. Technological Advancements

Automated Features:

Highlight recent technological advancements in bird fleshing machines. Explore features such as sensor technologies, automated adjustments, and adaptive learning systems that enhance their functionality.

Improved Precision:

Discuss how technological innovations have led to improved precision in feather removal. Analyze the impact of these advancements on the quality of processed poultry products.

6. Hygiene and Sanitation

Maintaining Food Safety:

Explore the role of bird fleshing machines in maintaining hygiene and sanitation standards in poultry processing. Discuss how these machines contribute to minimizing contamination risks and ensuring food safety.

Cleaning and Maintenance Protocols:

Detail the cleaning and maintenance protocols associated with bird fleshing machines. Emphasize their importance in preventing cross-contamination and ensuring the longevity of the equipment.

7. Impact on Quality of Poultry Products

Uniformity in Processing:

Discuss how bird fleshing machines contribute to the uniform processing of poultry carcasses. Explore the impact of this uniformity on the overall quality and presentation of poultry products.

Minimizing Damage:

Examine how the precise feather removal process minimizes damage to bird carcasses, resulting in higher-quality meat products. Illustrate the importance of intact and undamaged poultry for market presentation.

8. Customization and Adaptability

Versatility in Operation:

Explore the customization options available with bird fleshing machines. Discuss how these machines can be adapted to different bird species, sizes, and processing requirements, showcasing their versatility.

Adaptation to Industry Needs:

Highlight real-world examples of bird fleshing machines adapting to specific industry needs. Illustrate how customization contributes to their widespread adoption across diverse poultry processing facilities.

9. Economic Considerations

Initial Investment:

Examine the economic considerations associated with the integration of bird fleshing machines. Discuss the initial investment costs, including the purchase of equipment and any necessary infrastructure adjustments.

Operational Savings:

Explore how bird fleshing machines contribute to operational savings. Discuss factors such as reduced labor costs, increased production efficiency, and their cumulative impact on the overall economics of poultry processing.

10. Human Labor Reduction

Shift in Work Dynamics:

Discuss the transformative effect of bird fleshing machines on work dynamics in poultry processing plants. Explore how the reduction in manual labor allows skilled workers to focus on more intricate and value-added tasks.

Skill Utilization:

Examine the shift in the utilization of labor skills, emphasizing the importance of skilled workers in overseeing and managing automated processes within poultry processing facilities.

11. Environmental Impact

Energy Efficiency:

Explore the environmental impact of bird fleshing machines, considering factors such as energy efficiency. Discuss how these machines contribute to reducing energy consumption in poultry processing operations.

Waste Reduction:

Highlight the role of bird fleshing machines in minimizing waste generation. Discuss their contribution to sustainable practices by optimizing the use of resources and reducing the environmental footprint of poultry processing.

12. Regulatory Compliance

Adherence to Industry Standards:

Examine how bird fleshing machines align with industry regulations and standards. Discuss their role in ensuring compliance with food safety regulations, processing guidelines, and ethical standards.

Certification and Auditing:

Highlight the certification processes and auditing mechanisms associated with bird fleshing machines. Explore how adherence to regulatory standards contributes to the overall reliability of poultry processing operations.

13. Challenges and Solutions

Maintenance Requirements:

Discuss potential challenges associated with bird fleshing machines, such as maintenance requirements. Explore proactive maintenance strategies and technological solutions to mitigate downtime and ensure continuous operation.

Adaptability Issues:

Examine challenges related to the adaptability of bird fleshing machines to different processing scenarios. Discuss how ongoing research and development address these issues, ensuring machines remain versatile in diverse settings.

14. Future Trends and Innovations

Ongoing Research:

Explore current trends and innovations in the field of bird fleshing machines. Discuss ongoing research initiatives that aim to further enhance the capabilities of these machines and address emerging challenges.

Integration with Industry 4.0:

Highlight the potential integration of bird fleshing machines with Industry 4.0 technologies. Discuss how concepts such as the Internet of Things (IoT) and data analytics may shape the future of poultry processing.

15. Industry Adoption and Case Studies

Successful Implementations:

Showcase real-world examples of poultry processing plants that have successfully adopted bird fleshing machines. Present case studies that illustrate the outcomes and benefits experienced by these facilities.

Lessons Learned:

Discuss the lessons learned from industry adoption, emphasizing best practices and challenges overcome by poultry processing plants in integrating bird fleshing machines into their operations.

16. Ethical Considerations

Humane Treatment of Animals:

Address ethical considerations related to the use of bird fleshing machines. Discuss how these machines align with humane treatment standards, ensuring that the processing of poultry remains ethical and respectful.

Ethical Labor Practices:

Explore the ethical implications of reduced manual labor and its impact on the well-being of workers in poultry processing facilities. Discuss strategies for maintaining ethical labor practices while embracing automation.

17. Global Perspectives

Regional Adoption:

Offer a global perspective on the adoption of bird fleshing machines. Discuss regional variations in their acceptance, taking into account cultural, economic, and technological factors influencing their implementation.

Collaborative Initiatives:

Explore collaborative initiatives between regions, industries, and research institutions to enhance the global adoption of bird fleshing machines. Discuss the potential for shared knowledge and advancements on a global scale.

Conclusion

In conclusion, the advent of bird fleshing machines has marked a significant milestone in the evolution of poultry processing. Their impact on efficiency, product quality, and ethical considerations has positioned them as a cornerstone technology within the industry. As technological advancements continue to unfold, the future promises even more sophisticated and integrated solutions that will further propel the poultry processing sector into a new era of sustainability and innovation. This comprehensive exploration serves as a guide to understanding the multifaceted aspects of bird fleshing machines and their role in shaping the future of poultry processing.

Frequently Asked Questions (FAQs)

1. What is a birds fleshing machine?

- A bird fleshing machine is a technological innovation designed for poultry processing. It automates the process of removing feathers from bird carcasses, replacing traditional manual methods with a more efficient and precise automated system.

2. How do birds fleshing machines work?

- Bird fleshing machines work through a series of automated processes. The carcass is positioned, and the machine employs mechanical methods to precisely remove feathers. Some machines incorporate advanced features like sensors and adaptive learning systems for increased precision.

3. What are the primary applications of birds fleshing machines in the poultry industry?

- Bird fleshing machines streamline poultry processing operations by expediting feather removal. They contribute to increased efficiency, reduced processing time, and operational cost savings in poultry plants.

4. How do birds fleshing machines enhance processing efficiency?

- Bird fleshing machines reduce the dependence on manual labor, leading to a significant reduction in processing time. Their automated features contribute to higher production rates, making poultry processing more efficient.

5. What technological advancements have been made in birds fleshing machines?

- Recent advancements include automated features, improved precision, and adaptability to different bird sizes and species. Sensor technologies and advanced mechanisms contribute to the overall efficiency of these machines.

6. How do birds fleshing machines contribute to hygiene and sanitation in poultry processing?

- Bird fleshing machines play a crucial role in maintaining hygiene and sanitation standards by minimizing contamination risks. Their automated processes reduce the likelihood of cross-contamination, ensuring food safety.

7. What impact do birds fleshing machines have on the quality of poultry products?

- Bird fleshing machines contribute to the quality of poultry products by ensuring uniform processing and minimizing damage to bird carcasses. This results in higher-quality meat products for the market.

8. Are birds fleshing machines adaptable to different bird species and sizes?

- Yes, bird fleshing machines are designed to be versatile, adapting to various bird species and sizes. Their customization options make them suitable for different processing requirements in the poultry industry.

9. What economic considerations are associated with the integration of birds fleshing machines?

- Economic considerations include the initial investment costs, operational savings through reduced labor, and increased production efficiency. The overall economic impact varies based on the scale of poultry processing operations.

Nextezone: Igniting Tomorrow's Potential with Innovation Today Innovate. Explore. Elevate. Nextezone – Where Vision Meets Innovation.

Nextezone: Igniting Tomorrow's Potential with Innovation Today Innovate. Explore. Elevate. Nextezone – Where Vision Meets Innovation.